Rotate your tablet

for a better experience

Rotate your tablet

for a better experience

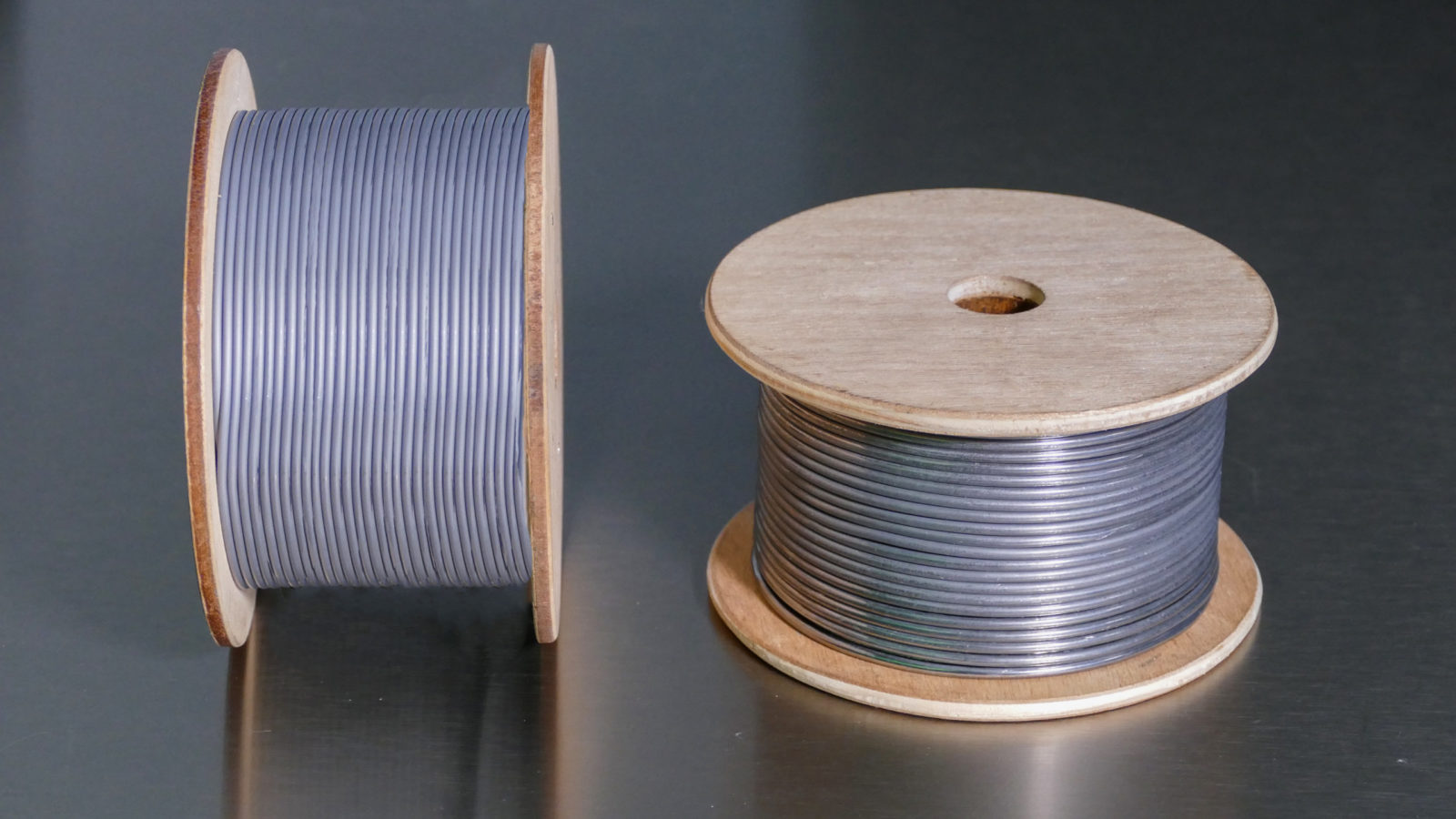

Pyroalliance designs and manufactures a complete family of detonating cords dedicated to

transmit a pyrotechnic signal, induce an ultra-short time delay or used for structure weakening /

breakage.

Those can be made of different metallic materials and various explosive types depending on the

application requirements. Pyroalliance has the ability to propose detonating cords with specific

plastic coating and/or armoured braiding.

More generally, Pyroalliance delivers complete pyrotechnic chains adapted to its customers’ needs.

They are designed and manufactured under Pyroalliance design authority.

Please scroll down to discover more specifications on multi-applications detonating cords :

Key figures, the complete product sheet to download.

↓

| TECHNICAL SPECIFICATIONS | OUR RANGE OF PERFORMANCE |

|---|---|

| DETONATING VELOCITY: | ~7000 m/s |

| EXTERNAL DIAMETER: |

~Ø 1.5 to ~Ø 5mm |

| IGNITION MODE: |

Detonation shock |

| OPERATING TEMPERATURE: |

Down to ~-80°C Up to ~+100°C |

| LINEAR LOAD: |

~0.5g/m up to ~10g/m Depending module |

| RELIABILITY: | Range of 1-10-6 |

| BENDING RADIUS: | Down to ~3mm with a ~Ø 1.5 transmission cord |